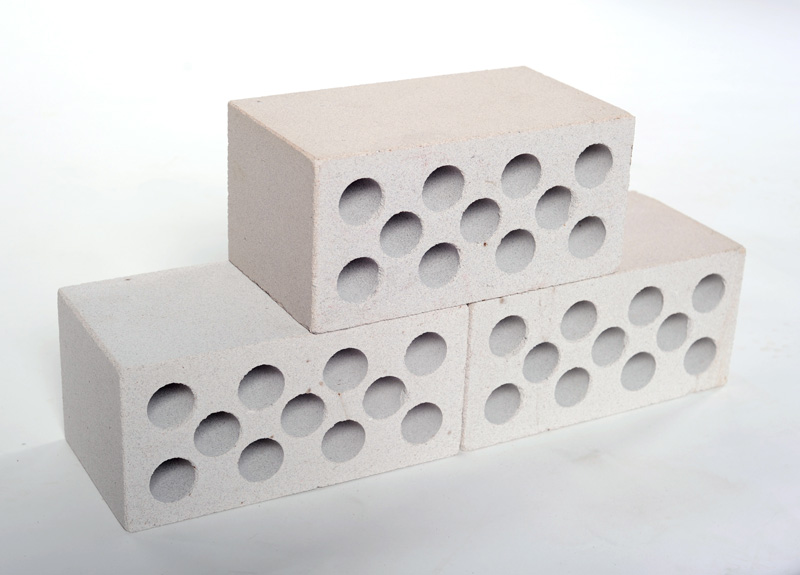

What is sand-lime brick?

Why Do Some Buildings Last Longer?

Some buildings develop cracks within a few years, while others stay solid for decades. The difference often lies in the choice of building materials.

This is where sand-lime brick (lime-sand brick) becomes a reliable, durable, and eco-friendly solution for modern construction.

What Is Sand-Lime Brick?

Sand-lime brick is not a traditional clay brick. Instead, it’s the product of:

- Material science

- Modern architectural needs

- Environmental awareness

Behind its simple appearance lies advanced engineering. This makes sand-lime brick a professional choice for sustainable and durable construction projects.

Composition of Sand-Lime Brick

The main ingredients of sand-lime bricks are:

- Silica sand – structural backbone

- Quicklime (CaO) – reactive binder

- Water – catalyst and shaping medium

The balance of these elements ensures optimal strength, durability, and uniformity.

How Sand-Lime Bricks Are Made

1. Hydration & Mixing

Quicklime reacts with water (hydration) → forms calcium hydroxide.

This bonds with silica → creates calcium silicate, the key to strength.

2. Pressing & Shaping

The wet mix is pressed into molds → high pressure removes air voids → uniform, compact structure.

3. Autoclaving (The Crucial Step)

Bricks are cured in autoclaves at 180–200°C under 8–12 bar pressure.

This completes the chemical reaction and forms stable calcium silicate crystals, making the bricks highly resistant to moisture, pressure, and temperature changes.

Standard Sizes & Weight of Sand-Lime Bricks

According to ISIRI 7782 (Iran) and DIN (Germany) standards:

- Standard brick: 71 × 115 × 240 mm → 3.2–3.6 kg

- Half brick: 52 × 115 × 240 mm → 2.4–2.8 kg

- Large engineering brick: 90 × 140 × 290 mm → 7–9 kg

Density: 1600–2000 kg/m³

Applications of Sand-Lime Bricks

- Interior & exterior walls (non-load-bearing)

- Light load-bearing walls (with reinforcement)

- Garden & boundary walls

- Industrial & warehouse buildings

- Buildings in semi-dry to dry climates

Advantages of Sand-Lime Bricks

Technical Benefits

- High compressive strength

- Low water absorption

- Fire resistance

- Uniform size & smooth surface → faster construction

Environmental Benefits

- Lower carbon footprint (low-temperature production, no fossil fuel kilns)

- Excellent thermal insulation → energy efficiency

- Clay-free → preserves natural soil resources

Limitations

- Not suitable for very humid or rainy climates

- Requires autoclaving → higher initial production costs

Conclusion: Future-Ready Building Material

Sand-lime brick offers more than just durability. It provides strength, sustainability, and energy efficiency—qualities essential for modern construction.

If you want a material that supports eco-friendly building practices while delivering structural reliability, sand-lime brick is the smart choice.

FAQ About Sand-Lime Bricks

- Is sand-lime brick stronger than clay brick?

Yes. Thanks to its dense structure and calcium silicate bonding, it has higher compressive strength than most traditional clay bricks. - Are sand-lime bricks eco-friendly?

Absolutely. They are produced at lower temperatures, use no clay, and offer good thermal insulation, making them a sustainable choice. - Can sand-lime bricks be used in humid climates?

They perform best in semi-dry to dry regions. For high-humidity areas, additional protective measures are recommended. - What are the common applications?

They are used in interior/exterior walls, boundary walls, industrial projects, and light load-bearing constructions.

Comments

Your feedback is important to us. Please share comments or ask questions you haven’t found the answer to yet.