Types of bricks in terms of use in construction

Brick is a building material that has been consistently used throughout history in construction as an essential and irreplaceable element in most ancient, historical, and modern structures. Archaeological findings show that the use of brick dates back 7,000 years, with early humans using earthen bricks for buildings and walls.

Today, this important construction material has seen significant advancements in quality and aesthetics thanks to technological progress. In addition to being used for wall construction, bricks are now widely used in facades, flooring, and decorative applications. Moreover, various types of firebricks are utilized in industry and the construction of industrial furnaces.

In the following, we aim to introduce you further to this material and outline the different types of bricks and their uses.

What is Brick?

Brick is one of the most important building materials, widely used in various types of construction. This construction material is made from different types of clay along with certain additives such as sand, lime, iron minerals, sodium, magnesium, and more.

The addition of various additives to the brick mixture increases its strength. The prepared materials are ultimately combined with a specific percentage of water, compacted, and then shaped into bricks—usually in rectangular block forms—through a baking process at specific temperatures.

The brick manufacturing process consists of several stages, including crushing and mixing the selected clay materials, moistening the mixture with water, compressing and molding, drying, firing, and cooling.

There are different types of bricks, and selecting the appropriate type for each application depends on their physical and chemical properties—such as pressure and heat resistance, appearance and aesthetic value, and their relative insulation against sound and heat. Due to its ease of transport, installation, and implementation compared to other building materials, brick has become one of the primary materials used in construction.

suggested article in English : Types of Facing Bricks and Their Applications

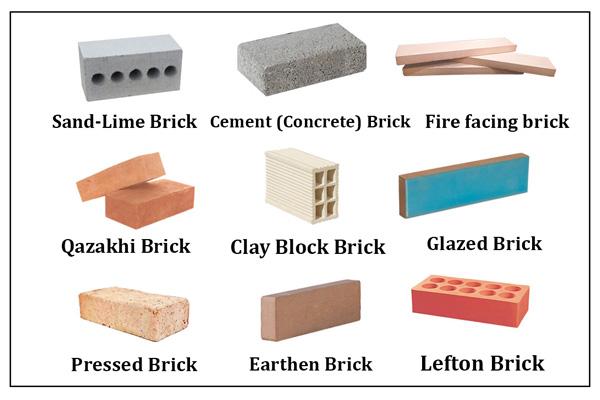

Types of Bricks by Type:

- Qazakhi Brick

- Clay Block Brick (Hollow Clay Brick)

- Earthen (Clay) Brick

- Pressed Brick

- Sand-Lime Brick

- Firebrick (Refractory Brick)

- Lefton Brick (Perforated Brick)

- Shale Brick

- Decorative Brick

- Cement (Concrete) Brick

- Glazed Brick

Qazakhi Brick

This type of brick, also known as traditional brick, is considered one of the oldest types of bricks in Iran—following adobe and regular mud bricks. It typically has dimensions of 20x 10 x 5.5 cm and is one of the best types of bricks for traditional wall construction.

Qazakhi bricks are generally larger and heavier than standard bricks. Due to their high strength and durability, they are used in historical structures and resistant buildings. These bricks are usually made from high-quality clay and baked in special kilns to enhance their hardness and strength.

In some regions, Qazakhi brick is regarded as a popular building material. Because of its natural and attractive appearance, it is also used in building facades. Overall, Qazakhi brick is a construction material with unique properties and a wide range of applications.

These bricks come in various colors such as reddish ochre, yellow, beige, peach, and onion-skin tones. Historically, they were commonly used in areas like Kazakhstan and other countries around the Caspian Sea, especially Iran and Russia. Qazakhi bricks are highly valued by builders and architects due to their resistance to freezing and heat.

Qazakhi bricks are available in various forms, including full brick, half brick, floor brick, and veneer brick (plaque). Based on appearance, they are also classified into plain plaque, rustic, and lined rustic types.

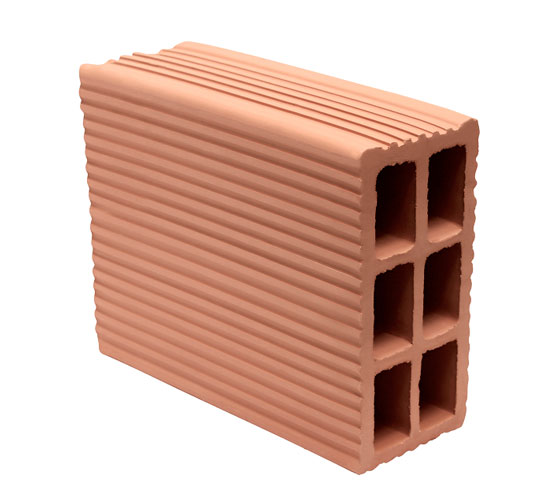

Clay Block Brick (Sofal Brick)

Sofal brick is a type of brick made from pottery clay and fired at high temperatures. Due to the clay content as its primary material, this brick typically comes in red or yellow tones. Sofal bricks usually have hollow cavities inside, which help reduce their weight and improve thermal and sound insulation.

Key features of clay block bricks include fast production, a variety of sizes, thermal insulation, lightweight, and affordable price. Due to their lightness, these bricks are commonly used in partition and interior wall construction and are recommended for multi-story buildings.

Another important characteristic is their easy bonding with mortar, which facilitates construction. Sofal bricks are especially used in walls, ceilings, and facades of buildings. Thanks to their many advantages, they are widely used in modern construction projects as well.

Earthen (Clay) Brick

Clay brick is a type of brick made from natural clay and other earthen materials. Due to its composition, it typically appears in red or yellow shades, depending on the type of clay used.

It is worth noting that clay brick is one of the oldest and most widely used construction materials. Its natural and attractive colors make it suitable for various structures, including homes, walls, and even historical buildings.

Since clay—the main ingredient—is relatively inexpensive, clay bricks are considered one of the most cost-effective and economical materials in the construction industry. These bricks can be used in facades under various environmental conditions, and they play an important role in both traditional and modern architecture.

Pressed Brick

Pressed brick is a type of brick produced by compressing soil and then firing it at high temperatures. Its composition typically includes clay, sand, cement, and water. After mixing these materials and subjecting them to high pressure and appropriate heat, the result is a very strong brick with a rough but smooth surface.

These bricks are known for their high compressive strength and durability, which makes them suitable for use in buildings and industrial structures. Pressed bricks are commonly used in the construction of walls, foundations, load-bearing structures, and also in exterior facades. Additionally, they have been used in the construction of historic and cultural buildings.

Sand-Lime Brick

Sand-lime brick is made from calcium silicate, combining sand, lime, and water, and is commonly used in building foundations. This type of brick has high compressive strength and load-bearing capacity, making it suitable for load-bearing, non-load-bearing, and retaining walls.

During production, pigments are often added, giving sand-lime bricks varied colors and an attractive appearance. These bricks also provide good thermal and sound insulation, helping to prevent heat from entering the building in summer and escaping in winter.

Sand-lime brick is easy to cut and shape, allowing designers greater flexibility and creativity in their projects. It is usually lighter than clay bricks, which makes transportation and installation easier. This type of brick is also known for its durability and long lifespan, performing well under various weather conditions.

Firebrick façade (Refractory Facing Brick)

Firebrick facade, due to its composition and method of production, exhibits high resistance to heat, fire, and harsh environmental conditions. These bricks are often used in high-temperature furnaces that are in direct contact with flames and are made from materials such as silicates, alumina, magnesium, carbon, kaolin, and other heat-resistant compounds.

There are two main types of firebricks based on their application: industrial firebricks and facade firebricks.

Industrial firebricks are used in various industries and industrial furnaces.

Facade firebricks, thanks to their insulating properties, high resistance to heat and moisture, strength under compressive and flexural forces, and aesthetic variety in size and color, are used in both interior and exterior building facades.

Different types of firebricks are selected depending on specific industrial needs, environmental conditions, and the required temperature resistance. Proper use of firebricks can significantly increase the efficiency and lifespan of thermal equipment.

Types of Firebrick:

Alumina Firebrick

This type of firebrick contains a high percentage of alumina and offers excellent resistance to heat and thermal shock. It is used where high resistance to temperature and fire is required, such as in industrial furnaces and industries like steel, cement, and glass production. Alumina firebrick is also used for manufacturing refractory facade bricks.

Silica Firebrick

Silica firebrick is primarily made of silica. It provides high resistance to elevated temperatures and has good thermal insulation properties. This type of brick is used in industrial furnaces, furnace linings, and for producing refractory facade bricks due to its attractive natural colors. Silica firebrick is commonly used in traditional and classic facades and has high resistance to temperature changes and moisture.

Alkali Firebrick

Alkali firebrick contains alkali materials such as potassium and sodium. It offers high resistance to chemicals and high temperatures and is used in alkali furnaces and chemical industries.

Chromite Firebrick

Chromite firebrick contains chromium and other oxides, providing excellent resistance to heat and oxidation. It is widely used in metal-melting furnaces and metallurgical industries.

Magnesite Firebrick

This firebrick mainly consists of magnesium and provides high resistance to very high temperatures and alkaline conditions. It is used in steelmaking and smelting furnaces.

Special Firebrick

Special firebrick is a combination of various materials tailored to specific project needs. It is designed for unique industrial conditions and applications, such as aerospace or energy production industries.

Insulating Firebrick

Insulating firebrick is made from lighter materials to reduce weight and increase thermal insulation. It has a low thermal conductivity coefficient and is used in furnace walls to minimize energy loss.

Lafton Brick (Perforated Brick)

Another name for Lafeton brick is the 10-holed brick or Bahmani brick, and it has a rectangular shape. This type of brick features large holes on its surface and is commonly used in wall construction, masonry, facades, and various structural applications in the building industry.

Lafeton brick is a type of machine-made brick produced using modern technology. Due to its light weight, uniform size, and ease of installation, it is widely favored by builders. Additionally, Lafeton bricks are generally larger than regular bricks, which reduces the number of bricks needed for a project and speeds up the construction process.

The perforated design of this brick provides sound and thermal insulation, helping to maintain suitable temperature conditions inside buildings. Its hollow structure improves its insulating performance. Moreover, Lafeton brick has high mechanical strength and can bear heavy loads.

Typically made from clay and other additives, Lafeton bricks are shaped and fired in kilns during production. Compared to some other brick types, they are lighter, making transportation and installation easier. They also tend to have lower moisture absorption, which enhances their durability in various weather conditions.

Lafeton bricks are used for constructing load-bearing walls, non-load-bearing walls, interior partitions, exterior cladding, and thermal insulation. Overall, due to its technical and economic advantages, Lafeton brick is a popular building material in many construction projects.

Shale Brick

Shale brick is made from a mixture of clay and shale soil, which is derived from crushed argillaceous sedimentary rock (shale). This rock primarily consists of fine clay particles, minerals, and various components such as quartz, calcite, and significant minerals like montmorillonite, dolomite, and albite.

Shale bricks are produced in six colors—red, brown, black, gray, white, and yellow—with the final color depending on how long the bricks are fired in the kiln. These bricks are used as facade bricks for both interior and exterior walls, as well as flooring. They are considered a good alternative to Qazakhi bricks, and due to the iron content in their composition, they have much higher strength than traditional clay bricks—making them suitable even for sidewalk paving.

Key features of shale bricks include:

- Good heat resistance

- Sound and thermal insulation

- High durability and strength

- Moisture resistance

- Lightweight

- Attractive appearance

Thanks to these qualities, shale bricks are an efficient and reliable material suitable for a wide range of construction projects.

Decorative Brick

Decorative brick is a type of brick that is widely used in interior and exterior design due to its variety of patterns, attractive appearance, and distinct decorative finish. These bricks are made from standard brick materials but feature unique surface textures and designs, giving architectural elements and building facades a more aesthetic and artistic look.

Decorative bricks are commonly used in flooring, walls, and building facades, offering both functionality and visual appeal in architectural projects.

Cement (Concrete) Brick

Cement brick, also known as concrete brick, is made from a mixture of concrete, which includes cement, sand, water, and other materials such as fibers and microsilica. These bricks are produced through casting in specific molds under controlled temperature and pressure conditions.

Glazed Brick

Glazed brick is a type of brick that has a coated surface layer of adhesive glaze. After the glaze is applied, the bricks are fired again to ensure the required strength and durability. The glaze gives the brick a distinctive shine and appearance, making it glossy, vibrant, and visually appealing.

Comments

Your feedback is important to us. Please share comments or ask questions you haven’t found the answer to yet.